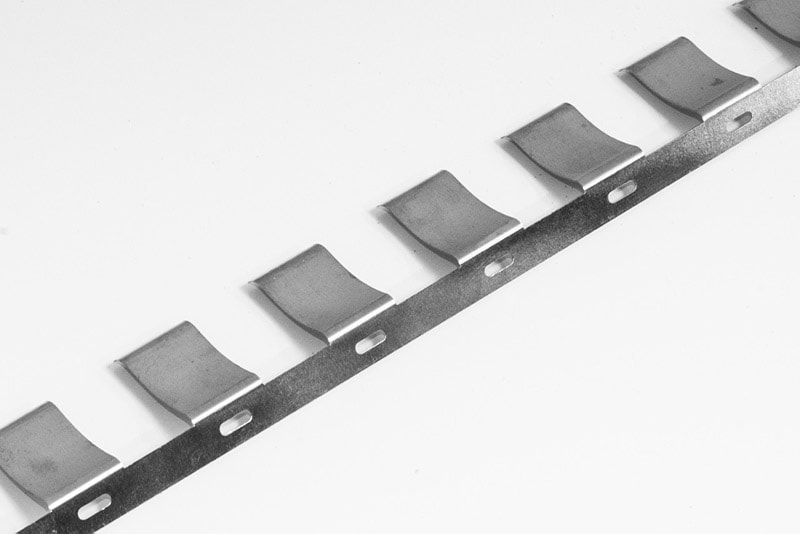

At Active Manufacturing Corp., we have specialized in quality prototyping and metal fabrication for nearly 30 years. Our reputation for precision metalworking is well-known and was instrumental in securing the project illustrated here. A customer in the medical industry required a custom-made test tube holder. This holder was challenging to make for several reasons. There were difficult conditions to overcome including handling coils that were .006” thick and 11.250” wide forming difficulties due to spring back. We employed extra high yield stainless steel as required by our customer’s specifications and used our 60 ton Komatsu Press to stamp and form this test tube holder. Our highly trained personnel utilized hand-fed processes, worked with die-cut blanks, and pick & place forming to produce prototypes for examination by our customers. After approval, we fabricated a short run order of test tubes with part dimensions that included a length of 11-1/4”, a width of 1”, a thickness of 0.006”, a weight of less than 1 lb. each, and tightest tolerances of ±0.001”. This project was completed in its entirety and delivered to our Michigan client within a timeframe of just three weeks. Our customer was pleased with the results. We have established a long-term relationship with this client, and now produce 5,000 to 10,000 of these test tube holders per monthly release as directed by our customer.

For more information about this project, please see the information in the following table, or contact us directly to find out how we can assist in your precision fabrication requirements.