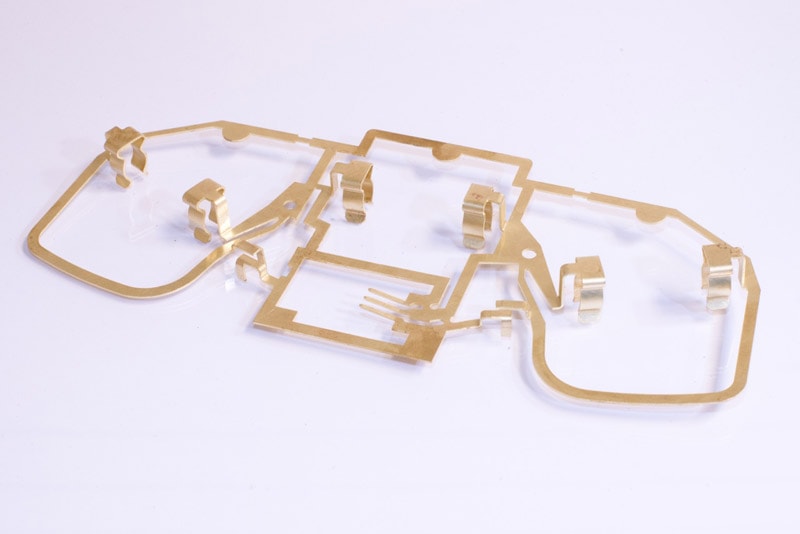

We pride ourselves on our longstanding relationships with clients from many different industries at Active Manufacturing Corp.. A customer in the automotive industry with whom we had worked before approached us to create a prototype of a dome light lead frame. We were pleased to take on this complex project, which required wire EDM machining and a total of 26 different forming operations. Using Beryllium Copper C17200, we employed our wire EDM machine and Pro Active Servo Press to machine and form this intricate frame, which required every bend to be formed individually. The finished part had overall dimensions of 7-1/4” in length, 3” in width, 0.025” in thickness, and weighed less than 1 lb. With our experienced personnel and advanced equipment, we were able to hold tolerances on this project to ±0.005”. Thorough dimensional and visual inspections were performed throughout the process to ensure that we met all of our customer’s specifications and that our work was of the highest quality. We were able to create and deliver this prototype to our Michigan client within just three weeks. Our customer was pleased with every aspect of our work and has enlisted us for numerous additional project partnerships since.

Please see the following table for details about this project, or contact us directly to find out how we can put our precision machining capabilities to work for you.